Safe Ripening Chambers

Fixed Gas Alarm Systems for the conservation and ripening process of fruit and vegetables

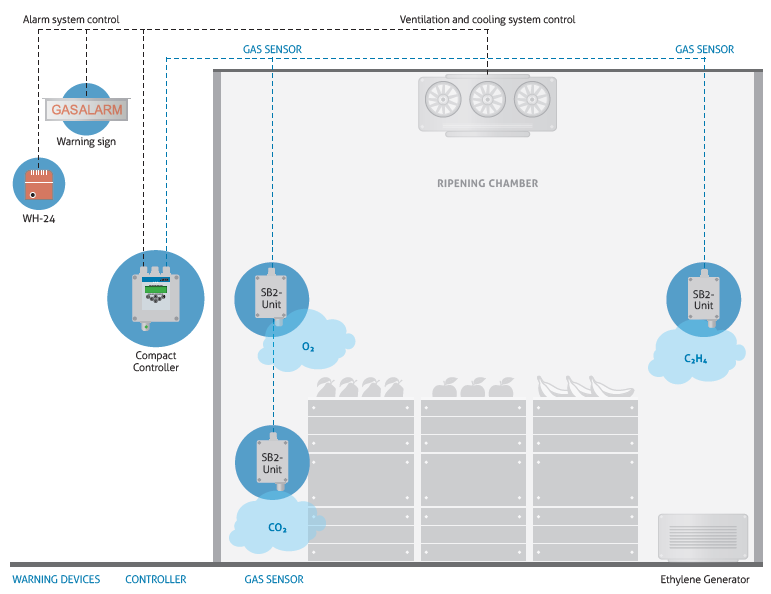

Ripening in controlled atmosphere Reliable monitoring of CO2 / C2H4 / C2H4O and O2 deficiency

Fresh fruit and vegetables are alive and continue to breathe after the harvest. This leads to oxygen consumption and the formation of carbon dioxide and water vapour. Keeping the products fresh means slowing down the process while maintaining the quality of the product. Gas sensors are just as important as the modern technology of the ripening chambers.

They are required to permanently monitor the various gas concentrations involved in the ripening process. The sensors, controllers and warning devices from MSR-Electronic protect people and equipment effectively and monitor the system as a central point of the entire process. Modern communication technology makes it possible to react quickly.

The innovative compact controller of the PolyGard®2 series from MSR-Electronic is de-signed for connecting up to 10 gas sensors via its own field bus, serves to warn of various gases and is therefore ideal for the application.

The process of banana ripening is probably the best known and consists of introducing ethylene into the storage room at concentrations around 150–200 ppm to accelerate the natural ethylene production of the banana itself.

FEATURES AND BENEFITS:

• Display for all displaying functions, configuration and calibration functions (no tool required)

• Fieldbus connection for up to 10 gas sensors (SB2-Units) with max.900m length

• Hardware and software according to SIL-compliant development process

• Modular technology (pluggable and exchangeable), reverse polarity and overload protected

• Internal function monitoring with integrated hardware watchdog

• 3 relays, 2 transistor outputs, 2 digital inputs

• Various housing types with IP65

• Warning buzzer and status LED for warning, fault, operation and service (optional)

• Operating voltage 230 V AC, with wide range input 100 to 240 V AC (optional), UPS (optional)

Should you have any questions or concerns regarding this matter, please feel free to contact us or reach our experts to info@alviautomation.com, sales@gasalarm.com.au

Be sure, Be safe – Gas Detectors and Alarm System