The PERFECT Gas Leakage and Measuring Solution for fruit Ripening and cold storage application

The Season of juicy sweet fruit mango’s comes, we in cold storage and Fruit Ripening chamber started working on it, in this period we dosing/use mango with ethylene gas and ammonia gas for ripening and storage and we all need to control & measure the amount of ethylene & ammonia we are supplying also need to aware about its leakage in open environment to control any hazardous incident, for all related solutions you can contact us any time .

ALVI Automation (India) Pvt Ltd in Association with GasAlarm Systems based in Sydney, Australia and MSR Germany specializing in gas detection & monitoring solutions with over 40 years of experience in the industry we like to think we know a little about the industry and how its , changed over the decades what we found lacking was good quality reliable products which were low cost, especially for the developing/emerging markets & countries.

So, we’ve taken it upon ourselves to slowly introduce such products one by one.

We dedicated to start with the most common product in gas detection worldwide, the humble ethylene and ammonia sensor Transmitter.

Countless brands, models & technologies exist however we feel ours has hit the spot when it comes to the all-important price/performance ratio.

We’ve kept it extremely compact! We’ve kept it extremely simple!

We’ll be honest, our aim is to sell this product at extremely low margins however in large quantities.Thus, ensuring you, the customer keeps buying and sees the value add in the product locally

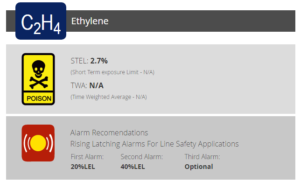

Introducing the Ethylene/Ammonia Sensor Transmitter

- The all-in-one sensor/transmitter is made in Germany under an OEM exclusive agreement for us.

- It uses an Electro-chemical sensor cell. NOT semi-conductor or MEMs semi-conductor.

- It offers an industry standard measuring range of Ammonia 0-1000 PPM and Ethylene 20-2000 ppm

- It runs on an industry standard 2 wire 24VDC current loop with a 4-20mA output.

- It has 2x onboard potentiometers for future on-going calibrations, A zero & a span/gain pot.

Please watch simple demo of our Gas leak Control and Monitoring System click here

Ethylene Sensor / Transmitters

- Ethylene solid state semiconductor range 20-2000 ppm

- Ethylene electrochemical range : 0-200 ppm

- High accuracy, selectivity and reliability

- Low zero point drift

- Long sensor life time

- Hardware & software according to SIL2 compliant development process

Ammonia Sensor/Transmitter

- Range 0-1000ppm or 0-10,000ppm

- Digital measurement value processing incl. temperature compensation

- Internal function control with integrated hardware watchdog

- Data / measured values in μC of the sensor unit, therefore simple exchange uncalibrated <> calibrated

- High accuracy, selectivity and reliability

- Low zero point drift

- Long sensor life time

· Hardware & software according to SIL2 compliant development process

For Pricing & Stock lead time please contact us or mail us at info@alviautomation.com