Low Pricing, Best Technology, High Accuracy, Long Life, Carbon Monoxide Gas Detector and Transmitter .

Benefits of CO Monitoring:

The very early sign in coal handling/processing plant fire is liberation of gas radicals (CO predominant). The idea is to detect the presence of this CO gas radical for very early fire prevention. By the time smoke is generated and detected it is already too late. A typical CO monitoring system for detection of products of combustion fires or spontaneous combustion of coal fires can warn potential fire two days in advance then flame is present or detected. By installing an effective CO and CH4 monitoring system, coal based power stations can benefit in the following ways:

- Reduced insurance premiums

- Better safety to plant and personals

- Reduced down time

- Prevention of loss of resources

- Save time and money.

Why CO monitoring? :

Coal contains moisture which when liberated, coal gets oxidised, generating both heat and carbon monoxide. This heat when builds-up has the potential of creating spontaneous combustion of coal fires.

Coal is extremely friable and can be easily crumbled or pulverised. Further coal also generates coal dust needing extra preventive measures like proper maintenance of stockpiles, guarding against accumulations of coal in the fuel-handling system, compaction of stockpiles, cleaning spills and washing float dust. The most effective programme for fire-prevention would be to have Carbon Monoxide Monitoring and Control System

CO Monitoring Installation Aspects:

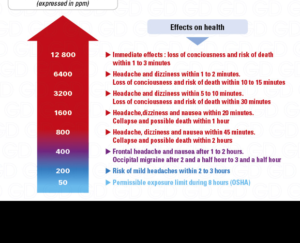

There will always be some safe background CO levels in coal handling or processing plants under normal operating conditions. These CO levels will rise during coal loading, handling and will again settle to normal levels once loading is finished and ventilation fans are running. It is important to find out the normal background CO levels by installing CO data-loggers and observing the CO generation trends under normal operating conditions of the plant. A typical CO level of 50 ppm of CO is normally present in background levels when coal is being handled, moved or transported. Based on these normal background CO levels the sizing/selection of the CO system (range etc) and alarm set points need to be undertaken.

Location of Sensors:

In general, it is wise practice to locate an adequate number of sensors at strategic locations based on knowledge of the potentials for ignition. When considering belt fires, sensors should be located in close proximity to drives, tail pieces, and main rollers.

When coal is the issue, any location where accumulation of coal dust or bulk quantities is likely or expected should be considered. These include belt transfers, crushers, dust collection systems, and storage bins (silos, bunkers, etc.).

System Approach:

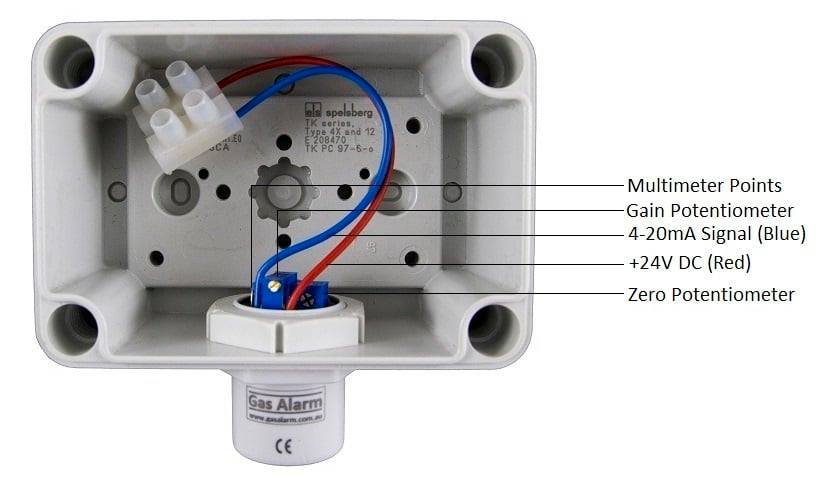

A typical system may consist of number of CO (range: 0-300, 500 or upto 1000 ppm) and or CH4 (range: 0-100% LEL) gas sensor/transmitters installed remotely at strategic potentially risky areas. The 4-20 mA output coming from these sensor/transmitters can be connected to a multi-channel gas controller which can handle from 2 to upto 96 remote sensor/transmitters. When CO concentration levels rise beyond the set limit (say above 100 ppm, depending on safe background levels), the built in relay contacts will automatically generate audio-visual alarm for plant supervisor to take corrective measure (ventilation fans, mains shut-off etc).

Fore more details Please read our article on CO Monitoring By Mr. Alak Jha : Articles-COearlyFire-CoalPowerPlants