Installation guidelines (FAQ) for Carbon Monoxide (CO) gas detectors in underground garages, parking houses and tunnels.

By ALVI Tags: Car park ventilation system, Installation guidelines (FAQ) for Carbon Monoxide (CO) gas detectorsWhat are the mounting heights for CO gas detectors?

- Carbon Monoxide (CO) gas has a slightly lower density than air. Recommended mounting height for Carbon Monoxide (CO) gas detector is 1.5 m above the floor.

- According in garages are concentrations expected less 1%VOL and because of thermal an convection of gas the spreading is at whole area.

How many CO gas detectors are needed in a stationary installation?

- There may exist some consultants, some local regulations or some country regulations, however, there are no absolute rules in determining the number of gas detectors and gas detectors location.

(EN50545 CO 400m²). - The number of gas detectors are to be decided from case to case depending on the situation of the location you want to detect and monitor.

- There are recommendations-guidelines (rule of thumbs).

One gas detector per 400 m2 (Coverage Area: 465 m2 to

930 m2 “Ideal Conditions” assumed using New Gas-DO-300-D) (i.e. one CO gas detector per 400 m2), plus additional gas detectors at the locations where gas leakage is likely to occur, preferably no farther than 1.5 meter (Mount at a height of 1.5 – 1.8 m above floor) where gas leakage is likely to occur.

What are the measuring ppm ranges for pre-alarm and warning alarm for CO gas detectors?

CO detectors alarm levels:

- Pre-alarm: 25 ppm.

- Warning alarm: 35 ppm.

- Fire alarm: 200 ppm

Measuring Range:0-300 ppm, Model no:GAS-CO-300-D

What is the gas sensor (cell) life time for CO gas detectors?

- CO gas sensor (cell) life expectancy is 6-10 years, normal operation environment.

- Fully sealed sensor cell, Gel type electrolyte not liquid type electrolyte with hydrophobic filter

- If gas sensor (cell) is intensively exposed for fumes (gas) the life time is shorter.

- If gas sensor (cell) is less exposed for fumes (gas) the life time can be longer.

Are the gas detectors needed to be re-calibrated?

- The CO gas detectors are pre-calibrated before delivery.

- The CO gas detectors are recommended to be re-calibrated on site or in-house once a year.

What to do when life time of gas sensor (cell) exceeded the expected life time ?

There are some different alternative choices, for examples:

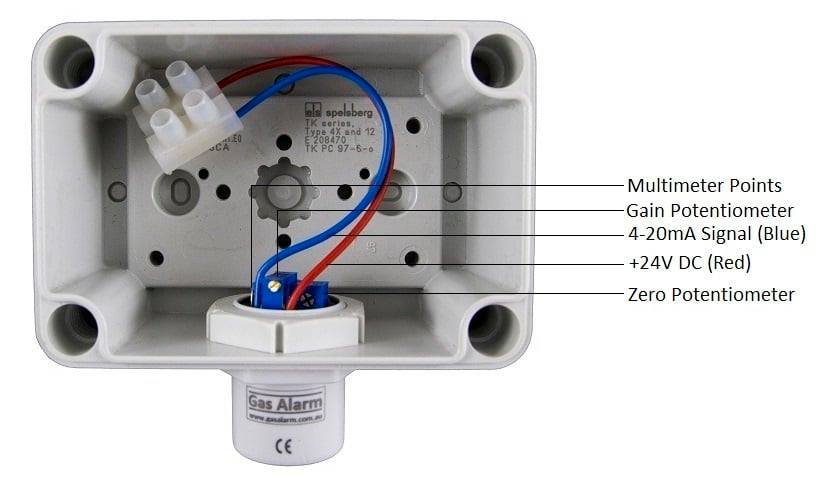

- New gas sensor (cell) can be ordered with re-calibration of the new gas sensor (cell) on existing PCB on site. For this alternative, the re-calibration instructions are needed to be followed very carefully. Recommended to be done of trained technicians.

- Existing PCB can be returned to ALVI Group OR MSR and new sensor (cell) can be ordered.

- The existing PCB can be factory pre-calibrated with the new sensor (cell).

- New factory pre-calibrated gas sensor (cell) and PCB can be ordered.

- Then the installer easily replace the existing gas sensor (cell) and PCB with the new factory pre-calibrated gas sensor (cell) and pcb. This is the easiest way of all above examples.

- The exchangeable sensor transmitter cartridge is our new concept to re-look on the Gas sensor and we are pleased to introduce Our most popular, most miniaturized exchangeable Carbon Monoxide (CO) sensor cartridge with cutting edge German Technology.

Click here to download the datasheet

Feel free to contact us if you’re interested in the product or have any questions.

Or write us an e-mail in the contact form below straight away.