Hydrogen Cyanide gas detection in Jewelry Industries

Jewelry manufacturers are increasingly worried about their worker’s health and safety conditions, Most jewelry companies want to prevent work-related illness and injury, and they also want to prevent pollution from their manufacturing processes, we have Smart Gas Detectors for Jewelry Manufacturing & Polishing Industries.

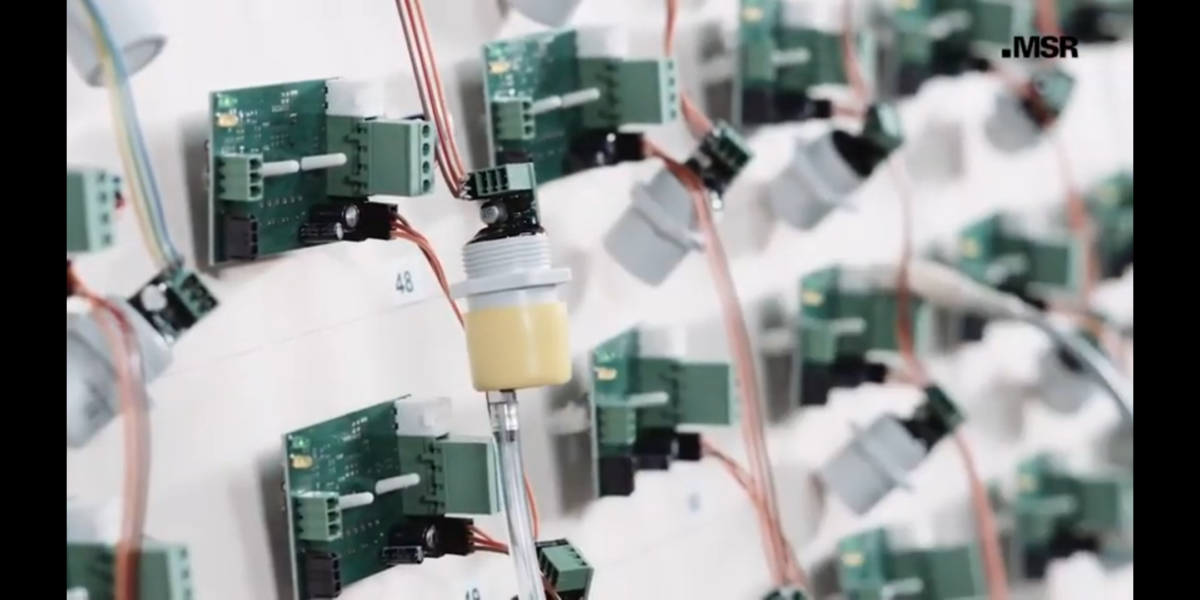

Most of the gases/solvent acid used or generate during the Jewelry polishing, Soldering, Dewaxing, process are like Cyanide, Hydrogen Cyanide, Hydrofluoric acid Sulphur dioxide , Nitric Oxide, Hydrochloride, Methyl Chloride, Cadmium, Acetone, Hydrogen, Methane, these gases are highly toxic and life threatening to avoid any unwanted accident the management need to install Smart MSR Germany Hydrogen Cyanide (HCN) Gas Detector, Sensor uses latest Electrochemical Diffusion type Sensing Technology to detect the Hydrogen Cyanide (HCN) with High accuracy in less time (Highly Responsive).

The 12bit Microprocessor Converter ensures the highest accuracy, sensitivity, selectivity and reliability despite the long calibration interval.

Click Here to see the On site demonstration video, Hydrogen Cyanide Gas Detection and Control Monitoring system installed at one of the gold design manufacturing Plant.

These gases or it’s vapor are very dangerous for human health, may cause Lungs cancer, Blood Cancer, Kidney, Liver damage, Cyanide gases are very dangerous for human life sometimes cause instant death.

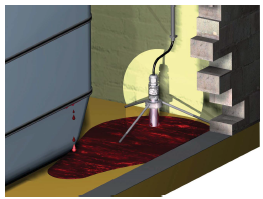

Since it comes under critical Human Life Safety, it is very important to Install authenticated, Gas Detection and Control Monitoring systems in the areas where these dangerous gases or solvent are used, so that it can be monitor, control & provide safe area to Work, definitely it will increase your productivity too when your worker do their work with secure mind.

We can help you in all your safety automation, gas detection needs, please feel free to contact us anytime at INFO@ALVIAUTOMATION.COM +91-7091777274