Sensor for combustible Methanol gas (CH3OH) Leak

ALVI Automation in association with Gas Alarm Systems – Australia pleased to introduce MSR Germany Methanol Gas Leak Sensor transmitter in Indian for Oil and petroleum Industries Market with following features.

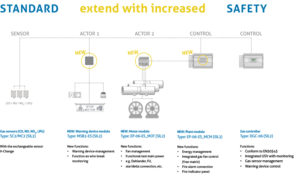

Microprocessor based gas sensor with 4 – 20 mA / RS485-Modbus output signal, alarm and fault relays (all SIL2 certified) for monitoring the ambient air to detect combustible gases and vapors within the lower explosive limit (LEL) by means of a catalytic sensor element (pellistor) or an infrared sensor element. The calibration of sensors without LCD display is carried out via the calibration device Cal PX or the PC software PC-Soft 80. Sensors with LCD display have an integrated calibration routine that is started from outside by a permanent magnet without opening the housing. In case of an alarm or fault the backlight of sensors with LCD display changes from green to red.

Continue reading “Sensor for combustible Methanol gas (CH3OH) Leak”