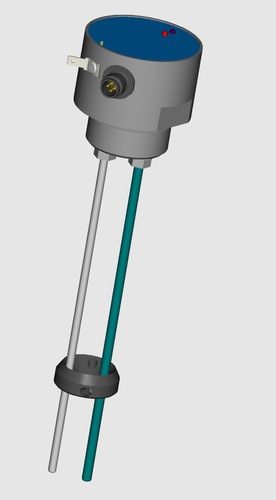

Digital differential pressure transmitter with 4-digit colour change LCD – DE39

ALVI – India in association with ALVI – Australia takes pride to offer Display and switching device for Differential pressure of gaseous and fluid media.

Typical applications

• Differential pressure measurements in heavily soiled media

• Filter monitoring

• simple pump control systems

• Pump, compressor monitoring

Design and mode of operation

The device is based on an electronic evaluation circuit that analyses the measuring signals P+ and P- of two integrated ceramic pressure transmitters. The signals are digitalised and sent to the analysis unit for further processing. Both signals can be shown separately.

The main feature is the calculation of the differential pressure. The analysis allows two independent switch points to be set and makes two programmable output signals available. The first output signal (channel 1) is proportional to the differential pres-sure and can be influenced by means of rooting or a table. The second output signal (channel 2) is proportional to the pressure and can be assigned optionally to the signal P+ or P-.

The nominal pressures of the integrated sensors and the differential pressure measuring range are set permanently ex-works and stated on the type plate.

Continue reading “Digital differential pressure transmitter with 4-digit colour change LCD – DE39”