Toxic Fixed Gas Sensor Transmitter

We need to Secure our workspace from Toxic gases by installing Toxic Fixed Gas Sensor Transmitter which works 24*7 hrs, we can say that ” We Secure Our Workspace/Home But Thereafter They Secure Us”

Toxic Fixed Gas Sensor Transmitter detects and informs before the toxic gases create any hazardous impact on humans and assets, in all types of Industries, Plant, Fruit Ripening Chamber, Cold Storage, hospitals, hotels, restaurants, Banking Sectors, Offices, homes, these sectors require high-quality globally trusted Gas Leak Detection Sensor Transmitter with Control Alarm Systems.

We have Best German range of products which are capable to control the panic fire in its initial phase before it begins or gets worst due to leakage of toxic gases like Oxygen, Carbon Dioxide, Carbon Monoxide, Ammonia, Ethylene, SO2, NO2, NO, etc, which meets global standard with high accuracy, fast response and long life in the economical price range.

Our Toxic Gas Detector has the following Features :

Technical Specifications:

- Measuring Parameters: Oxygen, Carbon Dioxide, Carbon Monoxide, Ammonia, Ethylene, SO2, NO2, NO, etc

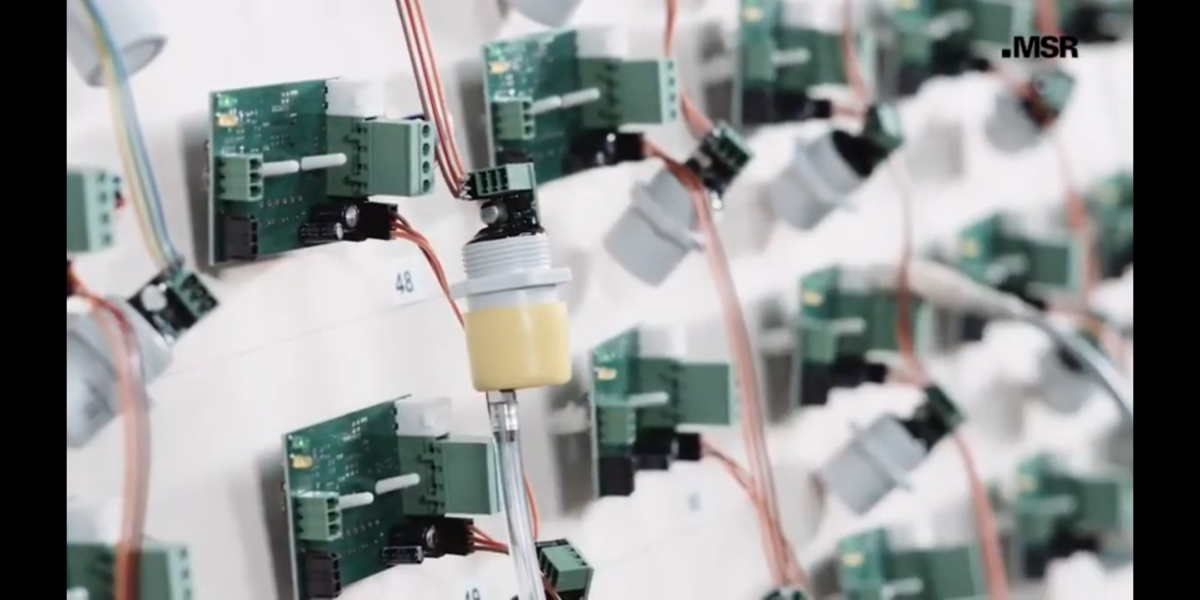

- Sensor Technology: Electrochemical sensor cell

- Measuring range: Depends on the Gas type

- Response time (t90): < 10 sec

- Control unit: 12-bit microprocessor-based

- Warm-up time: < 5 mins

- Auto zero point tracking for drift compensation

- Power supply: 24 VDC

- Ingress protection: IP 65, IP 66, IP 68

- Enclosure: Poly-carbonate material, also available in Stainless steel (for sensor cell), Cast Aluminium (for transmitter).

- Output: linear, proportional 4-20mA or 2-10Vdc

- Mounting: wall, duct, pipeline

- Safety integrity level: SIL 2

- Optional: LCD Display, alarm LEDs, potential-free relay contacts, Display Control Monitoring PLC HMI/PID Control Alarm Panel.

- Also Available for Hazardous area: Zone 1, Zone 2, Atex, IEC-EX, CE approved.

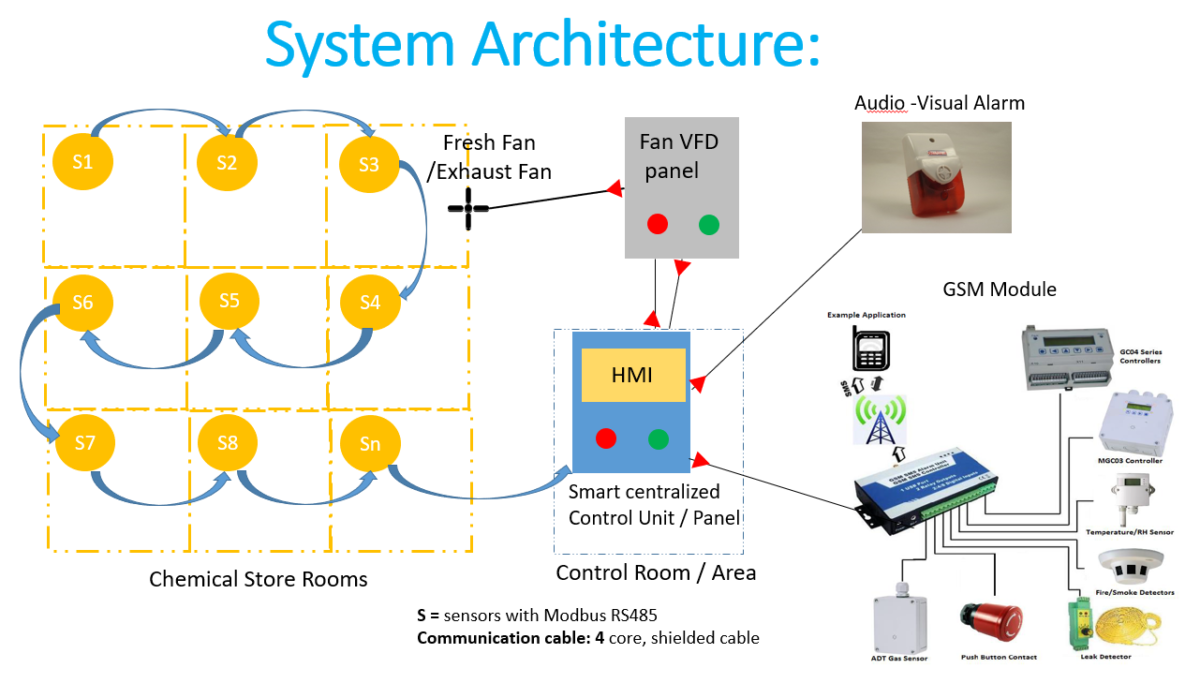

- Complete Customized Gas Detection and Control Monitoring Systems facilities available

For more details please feel free to contact us or email us to info@alviautomation.com

Please click on the below to know us more