Online Ammonia Gas Leakage Detection

ALVI Automation in association with ALVI – Technologies feel pleased to offer Ammonia Gas Leak Sensor Transmitter in Indian and Australasian countries to stop and control the hazardous tragedy caused by leakage of Ammonia gas from the food industries like cold storage, fruit ripening chamber and also from the chemical and gas factories .

Sensor offered by ALVI Group are having all advanced and new German technologies, as all these sensor are manufactured in Germany hence the quality and reliability are assured.

Ammonia (NH3) Gas Leak Sensor Transmitter Description are as follows :

Model no :MC2-D-E1125-C-X

Make : MSR German

- Measuring Range : 0-300/500/1000 PPM

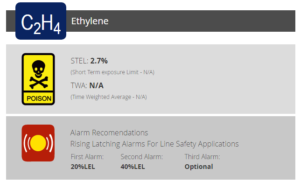

- Gas Type : NH3

- Sensor Cell : Electrochemical

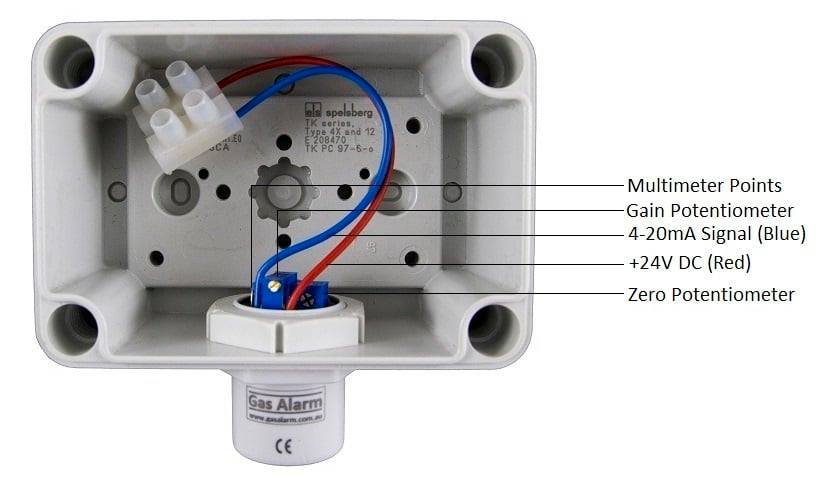

- Operating Voltage : 24 VDC

- Output Signal : 4-20 mA or 2-10 VDC

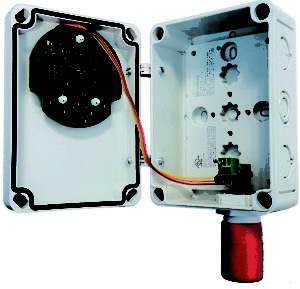

- Housed in IP65 polycarbonate enclosure

- Housing UL94 V2 approved

- Wall mount housing

- Calibration interval : 12 month

- Continuous Monitoring

- High accuracy, selectivity and reliability

- Low zero point drift

- Long life sensor

- Easy maintenance and calibration by exchange of the sensor unit or by comfortable on site calibration

- Software according to SIL2 compliant development process

For more details and quote please mail us on : Info@alviautomation.com