Carbon monoxide monitoring & control system for parking ventilation

Carbon monoxide and Very early smoke & fire sensor (VEFSA) transmitter

(Better monitor CO and CO+ which will solve the purpose of fire & Smoke monitoring as well as CO monitoring)

specifications:

- Should be capable of detection, measurement and monitoring of carbon monoxide and Carbon monoxide gas radicals

- Should have Electro-chemical type sensor cell

- Should have Gel based Electrolyte in the sensor cell

- Should have 0-300ppm measuring range, taking care over-rangenge detection.

- Should have high accuracy, high repeatability , high reliability

- Should have a coverage area of 700-750 m2

- Should a be 2-wire loop powered connection for power supply and signal output.

- Should analog output: 4-20mA (standard), 2-10V (3-wire loop) (optional)

- Should have linear, proportional

- Should have low response time: T90 < 50 sec

- Should have accuracy of ≤ 3% of measuring range.

- Should have low warm up time, ≤ 3 mins

- Should have Low voltage operation: 24V AC / DC

- Should have low power consumption: 22 mA, max. (0.6 VA)

- Should not be cross-sensitive to gases like SO2, acetone, ammonia, Carbon dioxide, Nitrogen dioxide, Nitric oxide.

- Should be wall mountable without need of further mounting brackets etc.

- Should have plug-in, easy replaceable sensor cell (simple push – pull arrangement) and PCB for easy service and replacement (no need to change the whole unit)

- Should have auto recovery to zero point

- Should have life expectancy of > 5 years, replaceable sensor cell

- Should capable of mounting in any direction, with no effect on performance, output and life of these sensors (no orientation problems)

- Should have poisoning protection, against background gases, lead vapours, dust etc

- Should have overflooding protection

- Should have reverse polarity and short circuit protection

- Should have manual trimpot calibration facility, with annual calibration frequency

- Should capable for field calibration

- Should have atleast IP44 protected housing, with the provision of dust and moisture protection with hydrophobic filter arrangement.

- Should have fast response time

- Should have IMMUNITY TO RF/FM INTERFERENCE as per the guidelines of EMC- Directive 2004/ 108/ EEC, CE

- Should have enclosure flammability in accordance to UL 94: VO

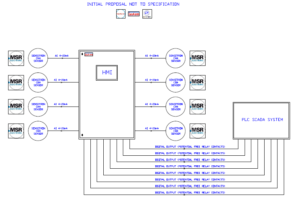

Central monitoring cum control system:

- Should be based on PLC or microprocessor based system with pre-defined logic retention capacity.

- Should have LCD or LED Display

- Should be able to expand analog input channel with help of slave or expansion module. No need to replace or change whole monitoring system

- should have free configurable set points at every channel input

- Should have facility to temporary disable any channel with key press or control device, for maintenance mode etc.

- Should have sufficient potential free (230VAC, 5A) relays. Should able to expand number of relays with help of slave / expansion modules.

- Relays should be capable of soft program, with one-to-one, one-to-many, many-to-one configuration with any channel set-points.

- Should be provided with contactor arrangement for operation, protection of exhaust fans, etc

- Should have overload protection arrangement

- Should have fault LED

- Auto-diagnostic watchdog with built in error code, fault LED indication informing about the type of system error/fault

- Should have password for protection against any un-authorised system access.

- Simple English Menu driven (system error, status alarm, status relay, MP parameter etc)

- Configurable relay parameters: energized, de-energized, latching, non-latching

- Should have provision / option for BMS integration via digital network.

Control & warning logic:

| CO concentration | Action |

| 0-35 ppm | No action. Display readout |

| >35ppm | Start fresh air & exhaust system (to reduce gas concentration) (lower speed) |

| > 60ppm | Start fresh air & exhaust system (higher speed) |

Control & warning logic: (with CO and CO+ monitoring for CO, fire and smoke )

| CO concentration | Action |

| 0-35 ppm | No action. Display readout |

| >35ppm | Start fresh air & exhaust system (to reduce gas concentration) (lower speed) |

| > 60ppm | Start fresh air & exhaust system (higher speed) |

| >200ppm | Send signals to fire alarm system and stop fresh air system |

Click here to download CO, Co+ datasheet

Click here to download controller datasheet

For more details pleae feel free to contact us or visit www.alviautomation.com